Textile production through the years

Textile production through the years

The production of linen had a long tradition in Gescher. In 1827 the town had 870 inhabitants, 44 of whom worked as full-time linen weavers. 351 peasants earned a sideline income as weavers. The flat, marshy meadows along river Berkel were well suited for bleaching the fabrics. In the 1830s and 1840s many families set up a loom in their homes, working as wage labourers. More and more cotton yarn was processed. This was imported by merchant traders who offset the price of the yarn against the finished bales of cloth, which they sold domestically and abroad. In Gescher, such merchant traders were Huesker & Butenberg (309 looms), F.J. Eckrodt (118 looms), J. Schulze (100 looms) and Conrad Gescher (85 looms), to name but a few. This system broke down when the yarns were no longer available during the American Civil War.

In 1861 H. & J. Huesker u. Co. founded the first mechanical weaving mill, which marked the beginning of the industrial revolution in Gescher. In 1905/09 a spinning mill was added. Merchant traders became manufacturers and cottage labourers turned into factory workers. These innovations changed the town’s economy, its society and town life as a whole. From 1899 to 1926, the power station of the Huesker textile factory supplied the entire town with electricity, and street lighting was installed. Eckrodt company was established in 1905. After World War I, the companies Gebr. Paskert, Greve & Co., A. Huesker & Schmiemann and Ignatz Hagmann were founded. Others followed after 1945, among them Hermann Schweers & Co., H. Eing and Gebr. Wittich.

For many decades, the local textile industry was the most important economic factor in Gescher and made its mark on the town. In spite of automation and opening up new fields of production, many of the local companies could not survive global competition in the 1960s and 1970s. But there are success stories, too. Huesker, by converting to synthetic geotextiles, has become world market leader in this field. The Greve weaving mill successfully produces functional fabrics. Eing company has specialised in textile finishing and trade.

When the local textile industry fell into crisis and lost its leading role, this had a serious impact on the structure of trade and jobs in Gescher. New strategies had to be found to compensate for the losses. For further details, please see Station B.

Webstube um 1830

1. Mechanische Weberei um 1863

In der Weberei Greve um 1910

Weberei Eckrodt um 1920

Dampfkessel für Fa. Eckrodt, 1930

Erweiterung der Fa. Eckrodt

Spulerei Eing um 1950

Textilverarbeitung in Nähereien

Zentrum der Textilindustrie

The Textile Industry as exemplified by Huesker company

The Textile Industry as exemplified by Huesker company

In 1861 the first mechanical cotton weaving mill in Gescher was established under the name H. & J. Huesker & Co.

In 1863, this new enterprise built a factory on the edge of town, near River Berkel and fitted it with state-of-the-art technical equipment. Only five years later, 200 looms were up and running there. In 1869 the company had the first telegraph station in the region. In 1885 Huesker built their own power station to supply the mill with electricity. A spinning mill was built in 1905 to become independent of yarn supplies. It was doubled in size in 1909.

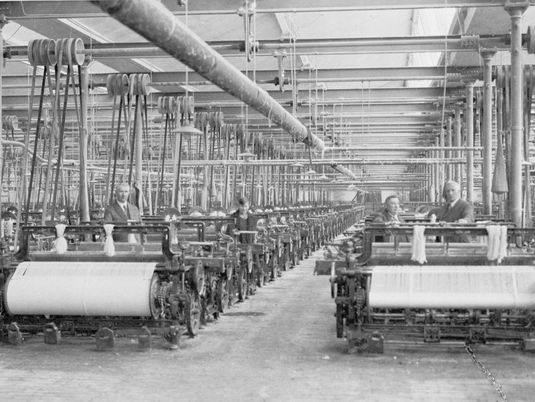

Around the year 1913, approximately 610 people worked in the spinning and weaving mill. A new weaving mill was built in 1923 in order to optimise production processes. Modern weaving, winding and sizing machines were installed in the years following.

In 1958 the company recognized the good prospects of synthetic materials and from the early 1960s took up the production of technical fabrics for hydraulic and civil engineering, alongside its traditional production. This evolved into HUESKER Synthetic GmbH & Co. in 1973. The parent company had to reduce the production of cotton fabrics due to strong competition, also from South East Asia, and stop production altogether in 1982. HUESKER Synthetic soon managed to fill this gap and to establish itself successfully on the international market. Since 1991 the company has also operated from the US.

The successful development of the company has continued to date. HUESKER Synthetic is now represented worldwide by a network of subsidiaries and sales partners. In 2007 sales figures exceeded 100 million euros for the first time. Today HUESKER Synthetic is a globally operating manufacturer of fabrics and textiles for various industries and applications.

The multi-functional geotextiles developed and manufactured by HUESKER Synthetic are high-tech products. They are used all over the world, often combined with innovative engineering solutions tailored to the individual case. Areas of application now include earthworks and foundation engineering, road and traffic route construction, infrastructure construction, hydraulic engineering as well as environmental engineering projects and the design of new landscapes (terraforming). These product lines could hardly have been imagined when the textile industry took off in the 1860s!

Ursprung der Fa. H. & J. Huesker & Co.

Eigene Spinnerei um 1910

Vorarbeiter und „Fabrikmädchen“

Spinnerei in den 1920er Jahren

Mensch und Maschine

Websaal in den 1950er Jahren

Kohlenlieferung

Seit 1990 Baudenkmal

Huesker- Synthetik – Gewebe

die Grundlage der A1 in Polen

The Spinning Works, an Industrial Monument

The Spinning Works, an Industrial Monument

Apart from the church of St. Pankratius, the Huesker spinning mill stands out as one of the town’s most impressive buildings. Around the turn of the 20th century, the local textile industry underwent fundamental changes. All work, from raw product to finished cloth, was now carried out centrally in the company and raw, imported cotton was processed into yarn in the company's own spinning mill.

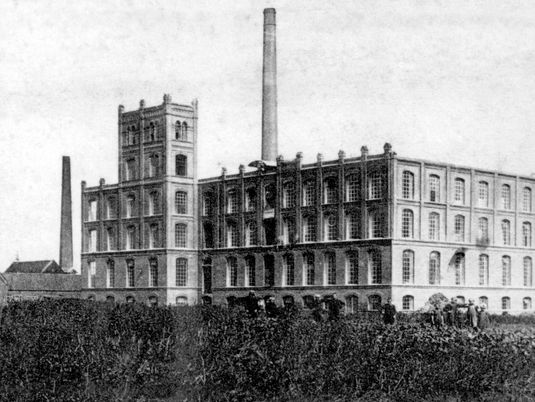

H. & J. Huesker & Co. built a spinning mill in 1905, designed by the Swiss engineers Sequin & Knobel from Rüti near Zurich. As early as 1909, an annex was added, which looked so much like the first building in shape and size that today, the two construction phases can hardly be distinguished.

The large factory served not only as a functional space, but also as the company’s figurehead. The machines were installed on several floors in rooms looking more like halls, and line shafts driven by steam provided the machines with power. A steel construction formed the supporting framework, which was able to withstand their dynamic loads. Weaving and spinning machines ran in shifts of 613 employees. Richly decorated brick facades in historal form with numerous battlements, turrets and many sash-bar windows arranged in rows expressed the self-confidence of the entrepreneurs.

The building was declared a top-class industrial monument in 1990.

The planners, who realised approximately 200 similar industrial buildings in Central Europe, equipped the factory with state-of-the-art technology, such as a machine and boiler house attached to the rear and a free-standing chimney. An area-wide sprinkler system was fed from an elevated tank incorporated in the five-storey west tower. A freight elevator transported machines and products between the floors.The fencing to the street is richly structured, based on design features of the main facade.

When the spinning mill fell into disuse during the 1980s textile crisis, various suggestions were made on its further use, ranging from town hall to textile museum. However, things turned out differently. Gescher built a new town hall. A textile museum was established in Bocholt, incidentally in a building that had been designed by the same planners in 1907. The two buildings strikingly resemble each other.

Today, the historic spinning works is home to civil engineers working on application technology and product development. Events and further training courses are held in a seminar area.

The spinning mill still embodies an important part of Gescher’s textile history even today, 115 years after its construction.

Gesamtsituation Huesker um 1910

Rohbau der Spinnerei um 1904

Fertigstellung 1905

Erweiterung um 1910

Schnittzeichnung

Bauplan zur Südansicht

Südseite heute

Nach der Sanierung 2002

Dominante Hauptfassade heute

Gegenstück in Bocholt bis 1945